Inflatable backing gas systems up to 300°C

Buitink Technology develops and produces inflatable backing gas systems for the controlled application of shielding gas to the inside of tubes or other closed profiles during welding.

Why is backing gas important?

When welding stainless steel, titanium or other reactive metals, it is crucial to protect not only the visible side, but also the back of the weld from oxidation. Exposure to oxygen at high temperatures leads to discolouration, brittleness and increased risk of corrosion.

Backing gas prevents this by displacing oxygen from the welding environment with an inert gas such as argon. This keeps the quality of the weld optimal - both visually and mechanically.

Our solution: inflatable systems for backing gas

Buitink Technology supplies inflatable systems that easily create a clean welding environment on the inside of a pipe or tank. The systems are cleverly designed, rapidly deployable and can withstand temperatures up to 300°C (572°F). They are reusable and suitable for a variety of pipe diameters and shapes.

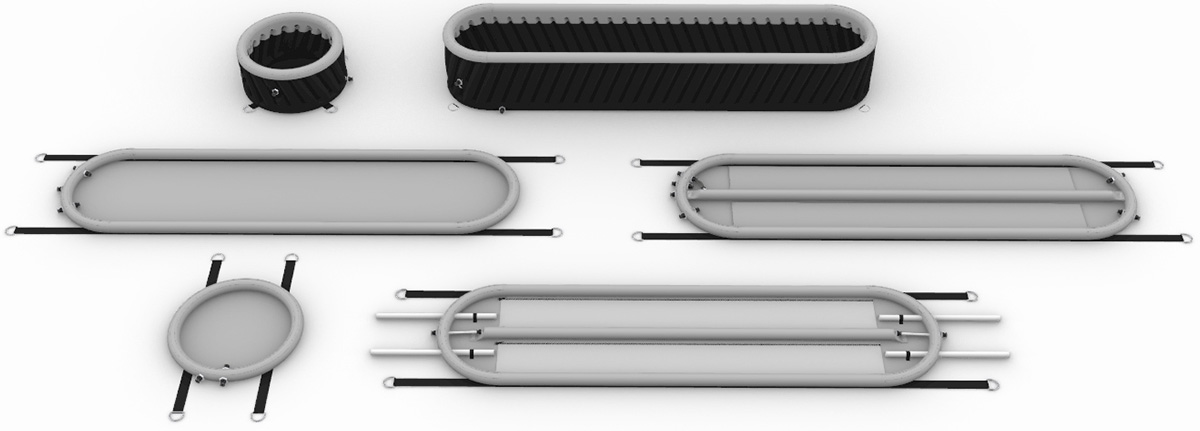

Image: Heat-resistant backing gas systems

How does our backing gas system work?

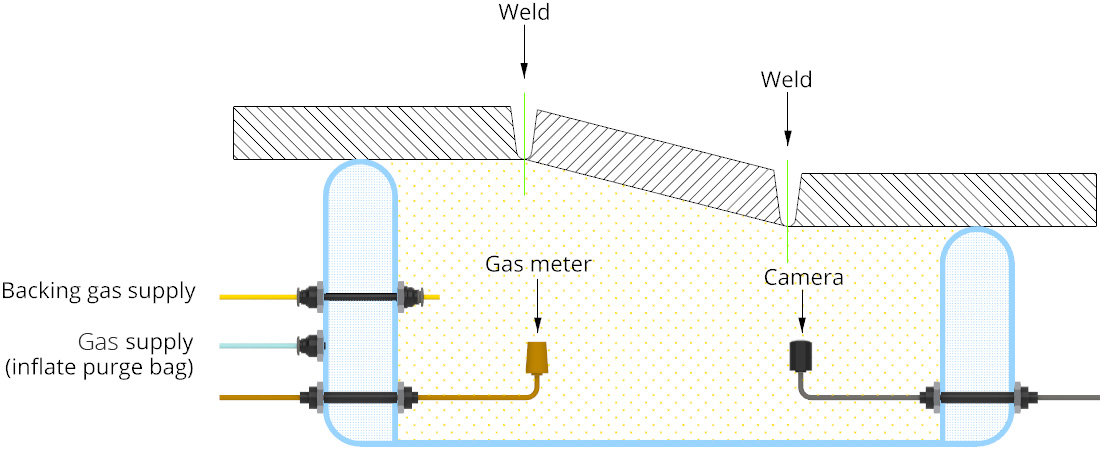

- The system is inserted into the tube on either side of the weld, or when welding thin sheets of stainless steel under the weld.

- The inflatable elements are filled with shielding gas (usually argon), sealing the tube airtight.

- The space between the elements is also filled with argon (or so the space under the weld) - this is the zone where welding takes place.

- During welding, the shielding gas keeps flowing to keep oxygen out.

- After welding, the elements are emptied and easily removed.

- Result is a super strong and save weld!

Illustration: Section of inflatable purge bag for backing gas

Advantages of our backing gas systems

Designed with practice in mind, our inflatable backing gas systems offer clear benefits for both the welder and the final quality of the workpiece:

- Temperature resistant up to 300°C→Designed for use in close proximity to the welding arc, resistant to high heat.

- Efficient gas consumption→Only the welding zone is filled with shielding gas - no wastage.

- Faster working time→Fast to install and remove, reducing production time.

- High weld quality→No discolouration, no oxidation or 'sugaring' on the inside of the weld.

- Reusable and durable→Longservice life and lower cost per weld thanks to robust construction.

- Tailor-made→Availablefor all pipe diameters, shapes and applications.

Available types of backing gas systems

Buitink Technology offers different types of inflatable systems, including:

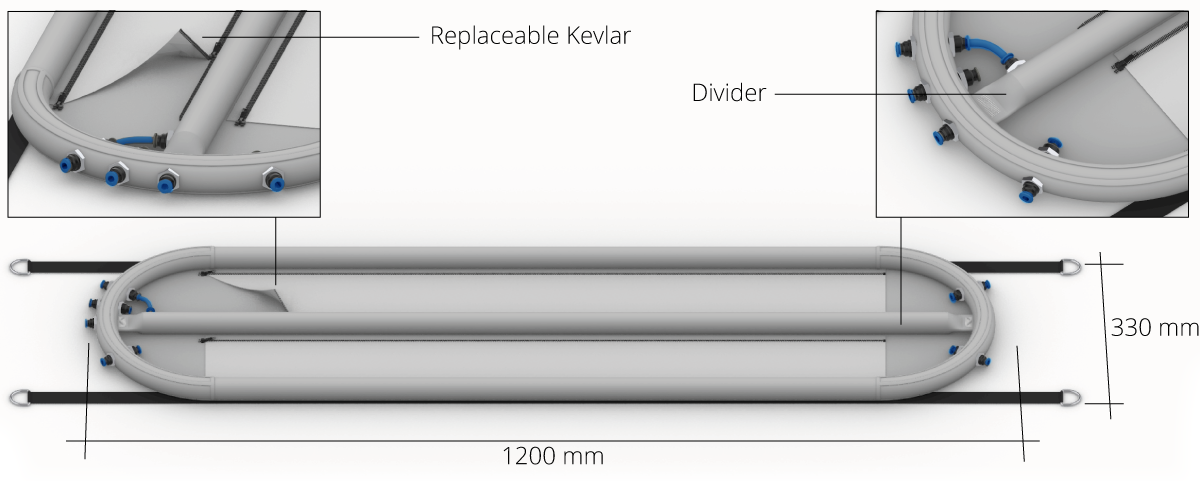

- Heat-resistant systems→Specially developed for use right next to the weld, made of materials such as Kevlar or fibreglass-reinforced silicone fabric.

- Inflatable gas-tight seals→Also known as shut-off dampers or welding dampers. These are inserted into the pipe to create a closed space filled with inert gas.

Application areas for backing gas systems

Our backing gas systems guarantee hygienic, strong and corrosion-resistant welded joints in the following sectors:

- Stainless steel and titanium piping systems→Pure TIG welding without oxidation, ideal for critical process piping.

- Apparatus engineering, tanks & pressure→Reliable tightness and long-term durability at high pressures and temperatures.

- Food & pharmaceutical vessels industry→Microbiologically safe welding seams according to HACCP and GMP guidelines.

- Chemical process plants→Optimal resistance to aggressive media and thermal shock.

- Energy & offshore sector (hydrogen, nuclear, oil & gas)→Guaranteed weld integrity under extreme conditions.

Commonly used shielding gases

Depending on the material and application, different types of shielding gas are chosen. Below is an overview of the most commonly used gases:

- Argon→The most widely used gas: inert, stable and suitable for almost all metals.

- Nitrogen→Good alternative for certain applications, but not universally applicable.

- Helium→Less common because of its price, but sometimes required for specific materials.

Example heat resistant purge dam

Useful and necessary for welding thin sheets of stainless steel. Our purge dam with replaceable Kevlar layers.

Questions?

Do you have questions or want more information? Please feel free to contact us. Call us at +31 (0)316-250830. But even easier: fill out the contact form below directly. We will contact you as soon as possible!

Contact form

Contact form +31 (0)316-250830

+31 (0)316-250830