Inflatable molds: safe, lightweight formwork

We have a reusable, flexible, and fully inflatable mold that replaces heavy steel formwork—developed for industrial processes involving concrete or refractory materials.

Traditional molds are heavy, unsafe, and time-consuming

Many industries still use steel molds to pour concrete or refractory material. These are large, heavy, and require intensive assembly and hoisting work in confined spaces. This poses risks to safety, ergonomics, and production time.

The inflatable mold from Buitink Technology

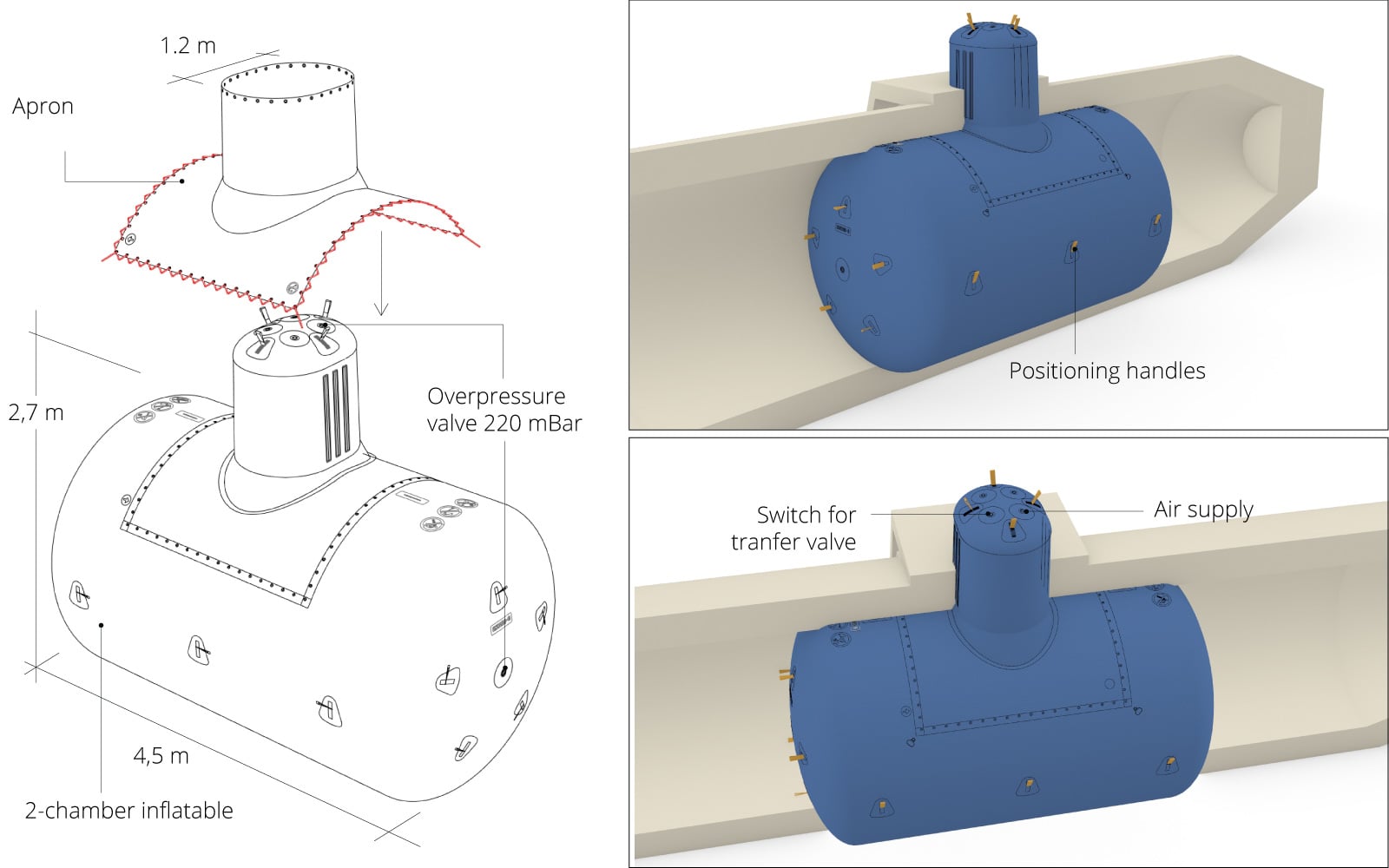

Buitink Technology developed a lightweight alternative: a reusable inflatable mold made of technical textiles. The mold is easily positioned when empty, then pressurized with air to form the exact desired geometry. Smart compartmentalization and pressure control keep the mold stable during the pouring of concrete or refractory material.

Waarom kiezen voor een opblaasbare mal?

- Safety: no heavy lifting, no hands on the load

- Ergonomics: assembly without lifting or crawling

- Speed: can be installed and removed in minutes

- Reusability: durable materials (aramid-reinforced fabric)

- Precision: constant pressure guarantees accurate shapes

- Low maintenance: easy to clean, replaceable protective apron

Lightweight, yet resistant to tons of concrete

The mold consists of multiple air chambers made of heavy-duty coated technical fabric that is resistant to wear, pressure, and temperature. With air pressure of up to approximately 0.2 bar, the structure can support more than 6 tons of concrete. Pressure relief valves and vacuum connections ensure maximum safety.

Suitable for temperatures up to approximately 250–300 °C with refractory materials.

Industrial mold engineering

Where can an inflatable mold be used?

- Pouring refractory components into furnaces or mixers

- Temporary formwork for concrete repairs or maintenance in tanks/silos

- Complex concrete shapes or architectural elements

- Prototyping and R&D applications in laboratories

- Formwork for composites or casting resins

Would you like to know whether an inflatable mold can improve your process?

You can simply fill out our contact form:

Global specialist in flexible and inflatable structures

With over 75 years of experience in technical textiles, Buitink develops unique solutions where conventional technology ends. From air separation and water dikes to industrial inflatables: our strength lies in combining material technology, design, and production under one roof.

Easy transport

FAQs

What is an inflatable mould from Buitink Technology?

An inflatable mould from Buitink Technology is a reusable, flexible formwork made of technical textile that replaces heavy steel moulds. The mould is easy to position when deflated, then pressurised with air to create the exact desired geometry for casting concrete or refractory material.

What are the advantages of an inflatable mould compared to traditional steel formwork?

An inflatable mould is lightweight and therefore much safer and more ergonomic to use. No heavy lifting or crane operations are required, and installers do not need to work in cramped spaces. The mould can be placed and removed within minutes, is reusable multiple times, and offers high dimensional accuracy thanks to the constant air pressure.

How strong is an inflatable mould and what loads can it handle?

The mould consists of multiple air chambers made from heavy, coated technical textile that is resistant to wear, pressure and temperature. At an air pressure of up to approximately 0.2 bar, the structure can support more than 6 tons of concrete. Pressure relief valves and vacuum connections provide additional safety during operation.

For which applications is an inflatable mould suitable?

Inflatable moulds can be used for casting refractory components in furnaces or mixers, as temporary formwork for concrete repairs in tanks and silos, for complex concrete geometries or architectural elements, for prototyping and R&D in laboratories, and as tooling for composites or cast resins.

Up to what temperature can inflatable moulds be used in refractory applications?

The inflatable moulds are designed for use with refractory materials at process temperatures of approximately 250–300 °C. This makes them suitable for heavy-duty industrial processes such as in furnaces, mixers and other high-temperature installations.

Questions?

Do you have questions or want more information? Please feel free to contact us. Call us at +31 (0)316-250830. But even easier: fill out the contact form below directly. We will contact you as soon as possible!

Contact form

Contact form +31 (0)316-250830

+31 (0)316-250830