Inflatable bend-tool

There are several different ways of bending PVC or plastic. Usually, the pipe is heated and bent around a rigid jig. Something is inserted into the pipe to prevent any kinking. Sand or a pipe-bending spring or – for larger diameter tubes – a heavy, flexible cylinder made of rubber can all be used for this purpose. However, the handling of heavy rubber tubes or bending jigs does not always comply with occupational health and safety guidelines. For example, due to the excessive weight that has to be moved by hand.

Buitink Technology makes inflatable bend-tools that are lightweight and therefore easy to handle. The Buitink Technology inflatable bend-tool is perfect for making bends in plastic pipes.

The bend-tool consists of an airtight core wrapped in a heat-resistant Multi-Layer High-Performance Fabric that can be inflated to the correct pressure needed for perfect bending results. The tool allows the easy bending of large-diameter pipes, and it can be custom made.

Advantages and key features

Buitink Technology’s inflatable bend-tool offers a variety of key benefits and properties:

- Extremely lightweight (a 200 cm x Ø20 cm bend-tool weighs no more than 5 kg);

- Customisation is possible;

- Heat resistant: operating temperature up to 150 degrees Celsius;

- Can create bends of different angles/radiuses possible;

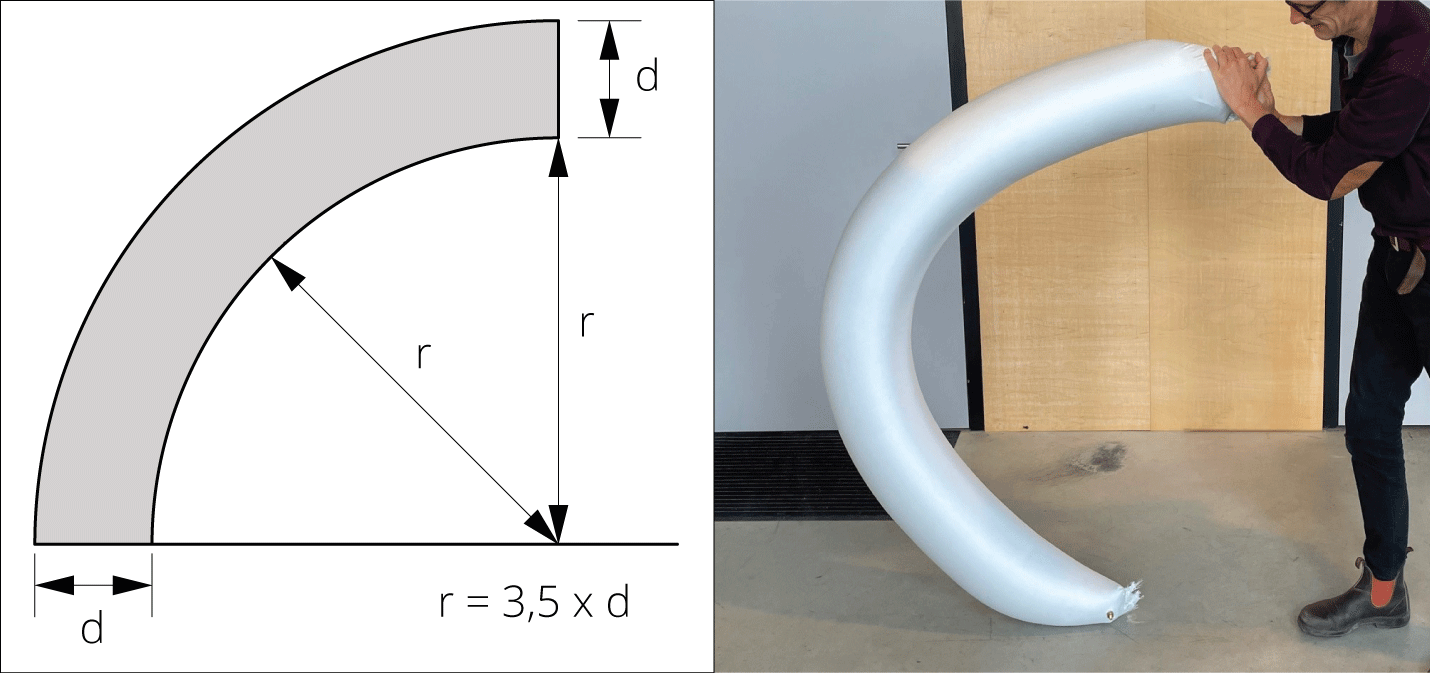

- It is possible to bend sharp angles: the bend-tool remains kink-free up to a radius of 3.5 x D! This means a PVC pipe with a diameter of 20 cm can be bent into a curve whose radius is no more than 70 cm!

- It is also possible to bend other shapes: for example, an S-bend or a pass over bend which is used to clear obstacles such as another pipe.

Specifications of inflatable bend-tool

As our inflatable bend-tools are custom made to suit each customer’s production process, we don’t make them to universal, standard specifications.

In general, all bend-tools that we produce meet the following specifications:

- Operating pressure: between 400 and 2,000 mbar (depending on the diameter);

- Heat resistant: maximum application temperature up to 150 degrees Celsius;

When do you use a bend-tool?

To bend plastic pipes or conduits without causing any unwanted deformation of the inner radius. To be able to shape the pipe or tube, it must be heated to a temperature at which the material becomes plastic.

What is the maximum temperature a which I can use the bend-tool?

To make it possible for the tube or pipe to be bent, it must be heated up. The temperature at which the pipe or tube can be plastically deformable depends on the type of plastic it is made of. The Buitink Technology Bend-tool can withstand an operating temperature up to 150 degrees Celsius.

What kind of air supply do I need to use the bend-tool?

You will need between 400 and 2000 mbar to bring the Bend-tool up to pressure. You can use a manual pump or compressor air, provided the pressure is reduced accordingly. We can adjust the valve on the Bend-tool according to your air supply.

What kind of material is the bend-tool made of?

Our Bend-tool is composed of MHPF (Multi-Layer High-Performance Fabric), which can be stretched in all directions, allowing it to fit perfectly to the shape of the radius of the plastic pipe or tube when under pressure. This controlled counter-pressure means the pipe or tube can be bent without deforming the inner radius or disrupting the flow.

What is the greatest benefit of MHPF composition?

Classic bending jigs are usually made of a rubber compound with walls at least 15 mm thick. The downside of this robust composition is that rubber bending jigs are extremely heavy. The Buitink Technology bend-tool weighs in at only a fraction of the classic rubber bending jig, making it much easier to handle.

Does the Buitink Technology bend-tool come in standard sizes?

We’ve noticed that our customers’ bending processes are never quite the same. That’s why before we proceed with production, we examine the customer’s requirements and their process. Generally speaking, we can supply a custom-made bend-tool for most diameters and lengths of pipes and tubes that will perfectly match your bending process.

What is the maximum angle that can be achieved using the bend-tool?

It is possible to bend sharp angles: the bend-tool remains kink-free up to a radius of 3.5 x D! This means a PVC pipe with a diameter of 20 cm can be bent into a curve whose radius is no more than 70 cm!

When do I put the bend-tool into position?

That depends strongly on the process used to plasticize and form the pipe or tube. The bend-tool’s light weight and the handles on the ends make positioning it and bringing it up to pressure before starting the bending process very straightforward.

What is the service life of the bend-tool?

This, of course, strongly depends on the conditions and how often it is used. Should the bend-tool be damaged during use, it can easily be repaired in our production facility because it is made of Multi-Layered fabric.

Are any additives required when using the bending process with the Buitink Technology bend-tool?

Classic heavy rubber bending jigs often need to be lubricated with soap or grease so they can slide in and out with ease. This is not necessary with the Buitink Technology Bend-tool because MHPF is very smooth, giving it very low shear resistance. Therefore the bend-tool is extremely easy to position without using greasy or contaminating lubricants.

Questions?

Do you have questions or want more information? Please feel free to contact us. Call us at +31 (0)316-250830. But even easier: fill out the contact form below directly. We will contact you as soon as possible!

Contact form

Contact form +31 (0)316-250830

+31 (0)316-250830