- Architecture

- Industry

- Leisure

- uk >

- Technology Center >

- Machinery and equipment >

- Pull and push test facility 300kN

Pull and push test facility 300kN

1. Description of 300 kN universal testing machine

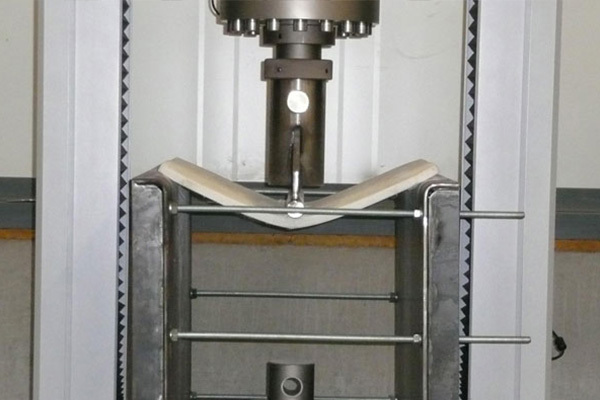

Buitink Technology has a 300kN universal testing machine that can be used to conduct compression, flexural and tensile tests up to 30,000 kg (30 tonnes).

We use this universal testing machine to carry out our own research and to support the development of products and materials. The universal testing machine is also used for project-based material and weld testing to guarantee excellent and consistent quality.

This testing machine is connected to a PC with advanced software so we can generate countless amounts of data and graphs.

1.1. Manual for 300kN universal testing machine

The 300kN universal testing machine manual includes the applicable safety regulations and possible testing methods.

Manual for 300kN universal testing machine

1.2. Universal testing machine2.5 kN

In addition to the heavy-duty 300 kN testing machine, we also have a small, light 2.5 kN universal tester:

2.5 kN universal testing machine.

This universal testing machine allows extremely precise testing of strips of single or double sheeting and textiles. We use this universal testing machine to test ETFE sheeting and the welds on ETFE sheeting.

2. Rental/testing of universal testing machine for third parties

Besides its use for in-house testing, our tester is also available for hire. You can commission us to carry out tests for you, or you can carry out tests yourself at our premises under our guidance. You then pay a start-up fee followed by an hourly rate for use of the universal testing machine/setup.

The great advantage of using our testing setup is that you can attend the test or even conduct your own tests under our guidance. This lets you can see how the test is performed, what happens and how the material being tested behaves under tensile, flexural or compression loads.

Not only is this very instructive, it also means you can avoid incurring any unnecessary costs: you may stop using the testing machine at any time, after which there are no costs to pay besides the start-up fee and the hours already worked.

Our flexibility also extends to allowing easy access to and use of our testing setup as testing can almost always be scheduled at short notice.

It is worth bearing in mind that we are not an accredited or certified testing institute.

This means we can carry out testing quickly and at a relatively low cost so you can find out whether your product, component, detail or material meets required standards and so you can make any additional improvements where necessary. You only have to send your product, material, component etc. to an accredited testing institute in the final stage of development to obtain the required or desired certifications without running the risk of having to repeat what are costly tests.

3. Tooling

3.1 Basic unit

Although we have a range of standard fixtures and grips for conducting tests, these are generally aimed at testing the tensile strength of webbing, fabrics and films.

You can find countless grips that can be used in combination with our testing machine on the manufacturer’s website. See Testometric grips.

In many cases, it is quicker, cheaper or necessary to make a specific tool or grip to allow proper testing of your material.

Our customers often arrange for the manufacture of tools that can be mounted on our testing machine. However, if required we can also design and make such a tool or grip for you.

To ensure that the tool/grip can be mounted on our testing machine, there are three basic methods of attachment: a cylindrical rod over which a mounting cylinder slides and is then secured with a pin, an M16 thread or an M20 thread.

More information about the different attachment options can be found below.

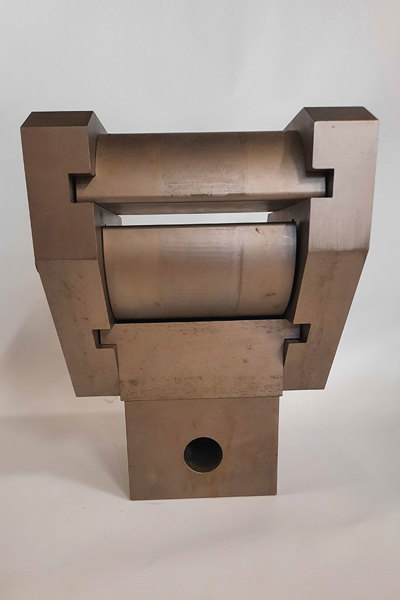

3.1.1 Testing machine tool/grip - Cylinder

In this case, a cylinder is slid over a cylindrical rod and secured with a pin. The grip in which the test product is clamped can then be mounted/welded onto this cylinder.

Download the PDF of the drawing of the basic unit for a cylindrical tool/grip here:

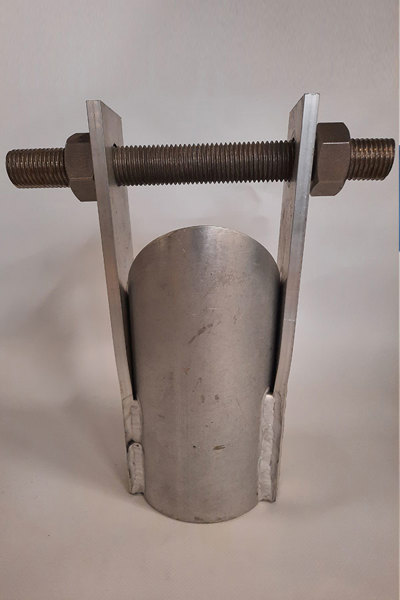

3.1.2 Testing machine tool/grip - M16

In this case, your tool/grip is mounted on an M16 thread.

Download the PDF of the drawing of the basic unit with an M16 thread here:

3.1.3 Testing machine tool/grip- M20

In this case, your tool/grip is mounted on an M20 thread.

Download the PDF of the drawing of the basic unit with an M20 thread here:

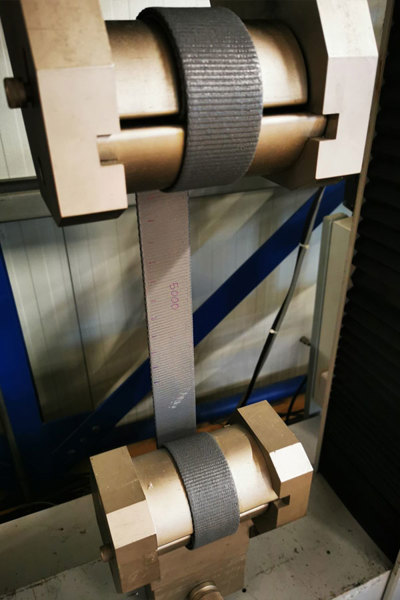

3.2 Tensile strength and elongation at break

The tensile strength is the maximum load a material can bear at a given amount of stretch/elongation. This grip/clamp can be used in the tensile strength and elongation testing of all kinds of flexible materials: coated fabrics, knitted fabrics, coated materials, geotextiles, carbon-fibre fabrics, textile glass woven fabrics, PVC-coated polyester fabrics, TPU-coated fabrics, silicone-coated glass fabrics, films, ETFE film, PTFE coated fibreglass fabric, etc.

3.3 Puncture resistance

With certain products, it is important and relevant to know the puncture resistance of the materials used. Puncture resistance is defined as the force required for a sharp object to penetrate a sample and cause, say, a leak or a weakening of the material.

For example, in the case of lifting bags and inflatable floats, puncture resistance must be as high as possible to minimize the risk of leaks during use.

To find out what a puncture resistance test looks like.

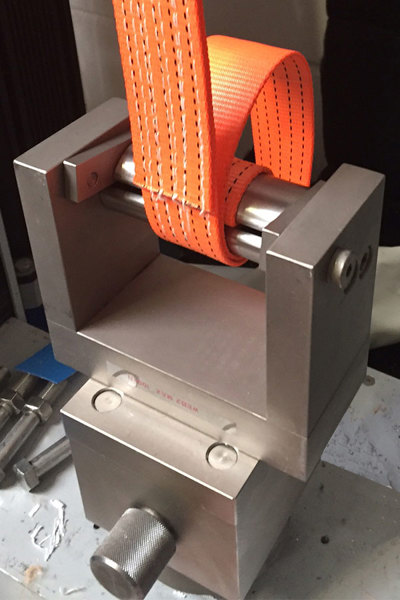

3.4 Webbing/lashing strap

For testing the strength of webbing/lashing straps up to 10 tonnes, we can fit a strap clamp to our testing machine: the Testometric WEB2-100kN - 100 mm wide

Click here for the specifications of this webbing clamp:

Click here for instructions on how to fit a lashing strap to the clamp for testing (and prevent slippage):

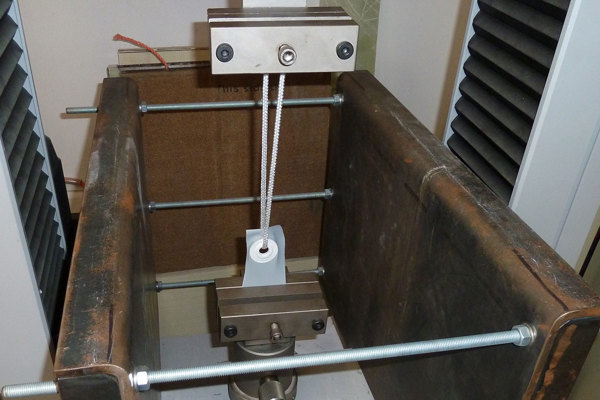

3.5 Various tools

Over the years, we have made and used numerous custom grips. See below for just a few examples of the wide range of possibilities.

- A grip to test the force/clamping force of an inflatable lifting device.

- A holder for testing the strength of a glued wood joint.

- A holder for testing parts for a helicopter.

3.6 Custom tools

The basic unit (see 3.1) can accommodate numerous custom tools and grips, allowing you to conduct your own specific tests tailored to your material and strength requirements.

3.7 Heat cabinet

In some cases, tests need to be carried out at temperatures higher than room temperature. For example, this applies when tensile tests have to be carried out on welds to obtain a German quality certificate issued by TÜV.

To obtain a quality certificate, both the material (stretch fabric) and its seams must undergo tensile testing at a temperature of 70 degrees Celsius.

We have a heat cabinet (with viewing windows) in which tests can be conducted at temperatures of up to 70 degrees Celsius.

3.8 Standards

Although we are not an accredited test institute, we can base our tests on certain standards.

3.8.1 Quality standard NEN-EN-ISO 1421

For the testing of coated fabrics, we work with the widely used quality standard: NEN-EN-ISO 1421:

Rubber- or plastics- coated fabrics - Determination of tensile strength and elongation at break (ISO 1421:1998)

3.8.2 NEN-EN-ISO 13934-1:2013

We also test in accordance with NEN-EN-ISO 13934-1:2013:

Textiles - Tensile properties of fabrics - Part 1: Determination of maximum force and elongation at maximum force using the strip method.

3.9 Calibration

Our testing machine is calibrated annually by the manufacturer, so you can be certain that our measurements are correct and accurate.

4. FAQ

How do I book an appointment to use the testing machine?

This is very easy. Just send an email to [email protected] stating when you want to conduct the test, what you want to test and how many hours you think you will need to use the testing machine. We will then get back to you to make the necessary arrangements.

How do I carry out tensile tests if I can’t operate a testing machine myself?

This is no problem whatsoever because testing is always supervised and conducted by one of Buitink Technology’s engineers. The costs are included in the rental price of the testing machine.

Can tests also be carried out under specific circumstances and conditions?

Tests are usually conducted under ‘office conditions’ in the area where the testing machine is set up. However, we can also carry out tests on materials under simulated temperature conditions. By putting a heat cabinet in place, tests can be conducted in temperatures of up to 70 degrees Celsius.

What size do the materials being tested need to be?

In order to be able to clamp the materials securely in place, they need to be of certain dimensions. We will let you know these dimensions and you will have to prepare them yourself before you can schedule and use the testing machine.

How accurate are the measurements taken by your testing machine?

The testing machine is calibrated annually so you can be certain that the test data is reliable and accurate. You can download and view the most recent calibration certificate from our website.

Do you record the measurements and results of the tests?

The testing machine is connected to a PC with advanced software. It can be used to generate numerous types of data and graphs that we can share with you in analogue or digital format as soon as the tests have been completed.

Are special tools required for conducting tensile tests?

Although we have a range of standard fixtures and grips for conducting tests, these are generally aimed at testing the tensile strength of webbing, fabrics and films.

If you need to test other kinds of material, you can find countless grips that can be used in combination with our testing machine on the manufacturer’s website: Testometric grips.

Are you a recognized or accredited testing institute?

No, we are not. Before you arrange for an accredited testing institute to conduct expensive tests for you, you can test your materials with us at a relatively low cost and make any necessary improvements. Then you can be certain that when it comes to final testing, your product can be certified without the risk of incurring extra costs.

How much will it cost us to rent the testing machine?

We rent the testing machine out per whole hour plus the fixed setup costs. The rental price includes supervision by a Buitink Technology engineer who also operates the testing machine.

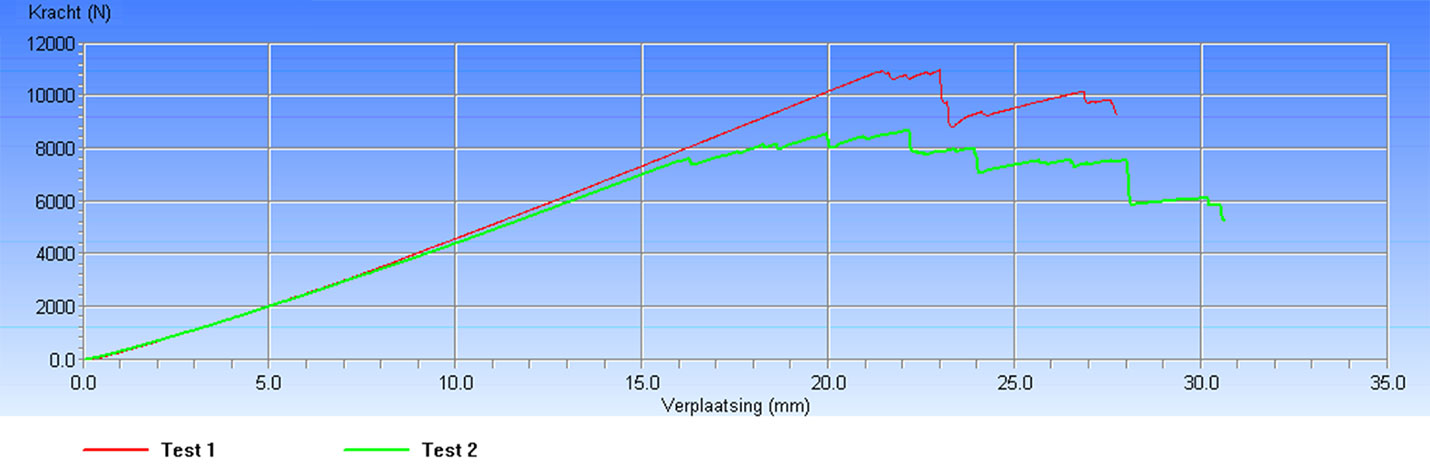

5. Universal testing machine printout

A typical printout from a 300 kN universal testing machine.

Questions?

Do you have questions or want more information? Please feel free to contact us. Call us at +31 (0)316-250830. But even easier: fill out the contact form below directly. We will contact you as soon as possible!

Contact form

Contact form +31 (0)316-250830

+31 (0)316-250830