- Architecture

- Industry

- Leisure

- uk >

- Technology Center >

- Engineering and consultancy >

- Floating system for transport

Floating system for horizontal and vertical transport

Buitink Technology not only produces inflatable floating cushions, but also develops and designs complete floating systems for specific projects.

1. Concept

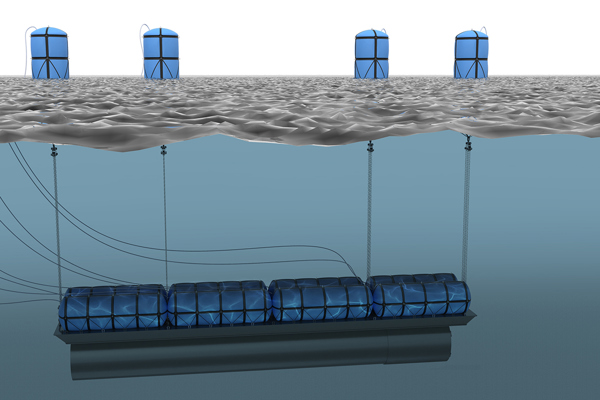

Below is shown the concept to integrate the required functionality for a project at sea in one single system without the need for a pontoon and a large crane.

2. Assignment

As an example the assignment to deliver multipurpose floats for a specific project (project: recovery of a submerged tunnel drill at sea). The various project steps:

- Moving a floating lifting frame (20 tons) from the harbour to the water location.

- To lower the lifting frame towards the tunnel drill at the bottom of the water area

- Lifting the frame including the tunnel drill to the water surface (total 185 tons)

- Moving the floating frame with tunnel drill back towards the harbour.

The required integrated functionally of the floating system (combined horizontal movement, lowering and lifting in water) is unique. To meet with the different demands we developed a fully new concept.

3. Our solution

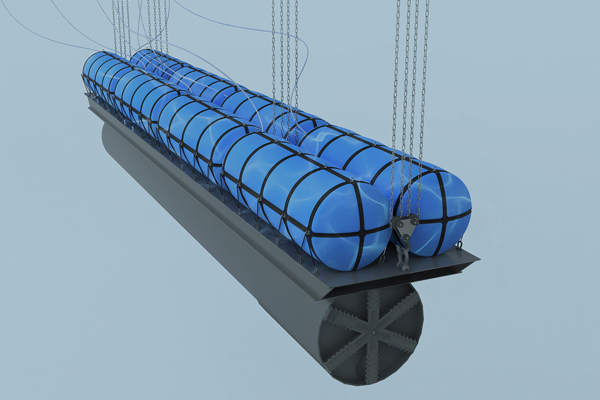

We developed a solution that envisaged a combination of a number of horizontal and vertical floats.

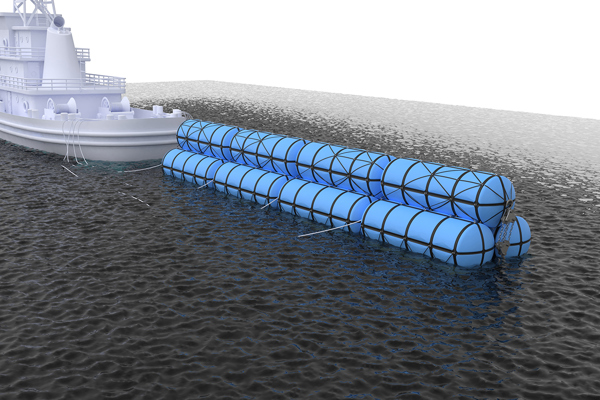

3.1 Horizontal floats

Horizontal floats are used to move a load floating on water (towards a location on water and backwards again).

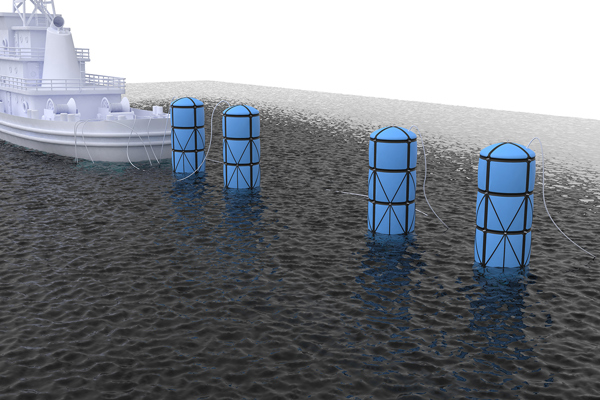

3.2 Combined horizontal and vertical floats

Combined horizontal and vertical floats are used to lower the lifting frame (20 tons) towards the bottom of the sea in a controlled way. Note that the vertical floats stay near the water surface; essential for a proper operation.

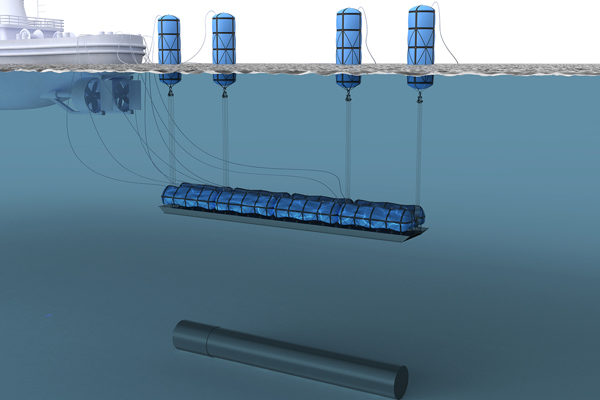

The challenge: During lowering the floats the water pressure increases. As a result the buoyancy of the floats is reduced such that the lowering without vertical floats would be uncontrolled with a continuously increasing speed. A combination of horizontal and vertical floats avoids this problem.

To lift the frame including tunnel drill (185 tons) up to the water surface under controlled conditions, horizontal floats combined with vertical floats are used. The vertical floats stay at the water surface partially submerged, essential for a guaranteed steady operation.

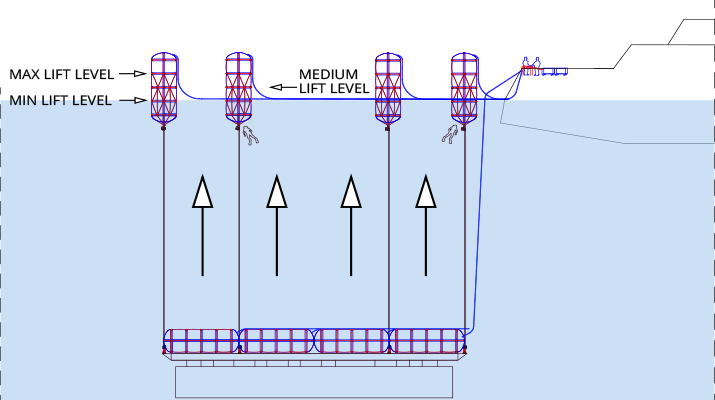

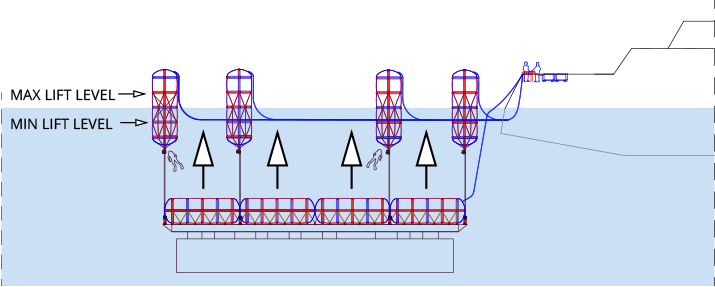

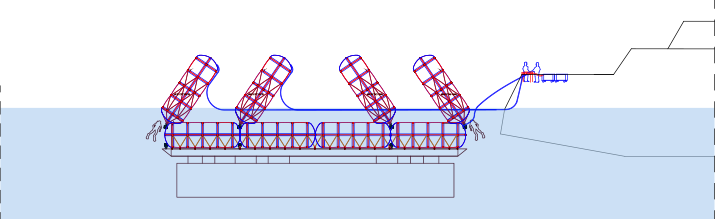

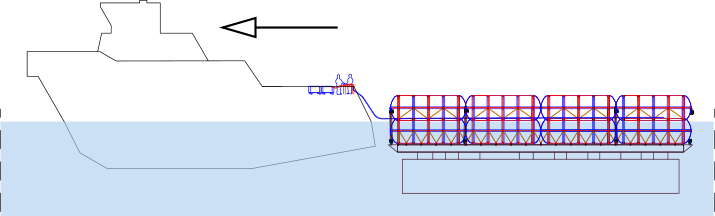

4. Visualizing the various process steps

Horizontal and vertical transport in various steps.

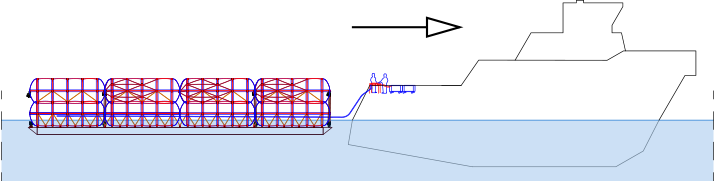

4.1 To location at sea

- Fixing all cushions to the lifting frame. These cushions carry the frame during transport of the frame to the location at sea.

- The floats, later-on in vertical position during operation, now are fixed horizontally on top of the horizontal floats.

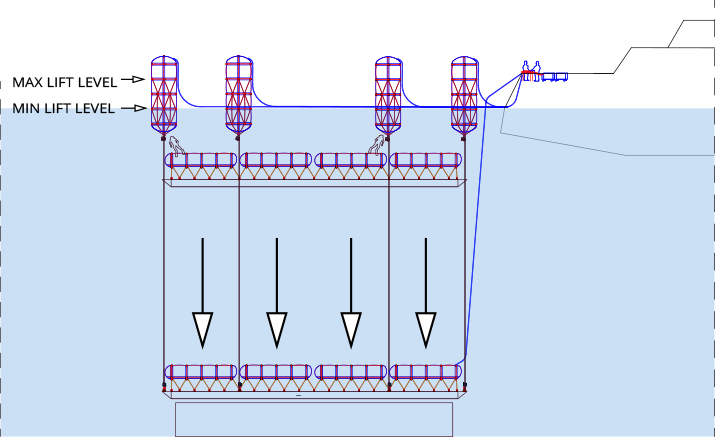

4.2 To lower 20Tons Frame

- Reducing air pressure in the horizontal cushions till the vertical floats carry the load (position at minimum lift level.

- Increase length of chains under water to enable lowering the frame in the water. The vertical cushions carry the frame. During descend of the frame the level of the vertical floats have to stay between MIN LIFT LEVEL en MAX LIFT LEVEL.

4.3 Start lifting the 20T Frame + 165T TBM from the sea bottom

- Anchor lifting frame to TBM.

- Shorten the chains in the water such that vertical floats are at position MAX LIFT LEVEL.

- Inflate horizontal floats such that vertical floats are at position MEDIUM LIFT LEVEL.

4.4 Lifting 20T Frame + 165T TBM towards sea level

- Shorten chains under water untill vertical floats are at position MIN LIFT LEVEL. The TBM moves upwards, increasing the buoyancy of the horizontal floats. This reduces the load on the vertical floats, so they move towards MIN LIFT LEVEL.

- Reduce pressure in the horizontal floats until the vertical floats move downwards till MAX LIFT LEVEL. De TBM will sink a little bit as the horizontal floats "feel" a heaviour load.

- Shorten the chains under water until the vertical cushions are at position: MIN LIFT LEVEL. The TBM raises so the buoyancy of the horizontal floats increases. As a result the vertical floats "feel" a reducing load and raise upwards towards position: MIN LIFT LEVEL.

- Repeat reducing pressure in horizontal floats and shorten the chains under water until close to sea level.

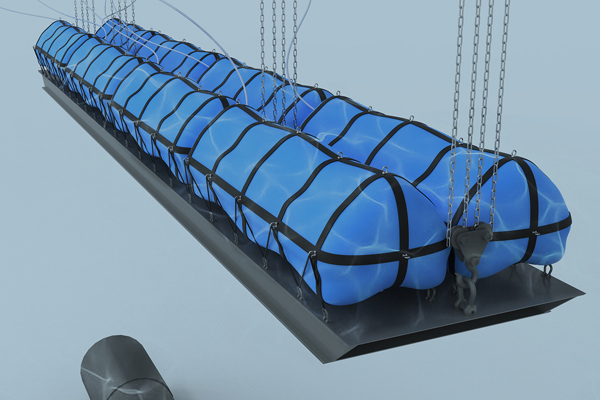

4.5 Situation during last 2 meter of lifting process

- At minimum length of the chains the vertical floats will tumble down.

- Inflate the horizontal floats till 1.1 bar above atmosphere.

- Fixing all cushions to the frame such that they all carry the frame during transport to the harbour.

4.6 Transport of 20T Frame + 165T TBM to the harbour

5. Manifolds en air compressor system

Besides development, engineering and production of inflatable floats, we also deliver accessories like manifolds and air systems. We also offer operational support on location during operation.

Questions?

Do you have questions or want more information? Please feel free to contact us. Call us at +31 (0)316-250830. But even easier: fill out the contact form below directly. We will contact you as soon as possible!

Contact form

Contact form +31 (0)316-250830

+31 (0)316-250830