Custom inflatable sewer valve

Buitink Technology received the order for the design and engineering of an inflatable valve for a concrete sewer shaft.

Purpose of the valve

The sewerage shaft concerned is regularly submerged in water, depending on ebb and flood tides, and rainfall.

During the installation of a hydro-turbine in the shaft, the shaft must be kept dry so that work can be carried out in it.

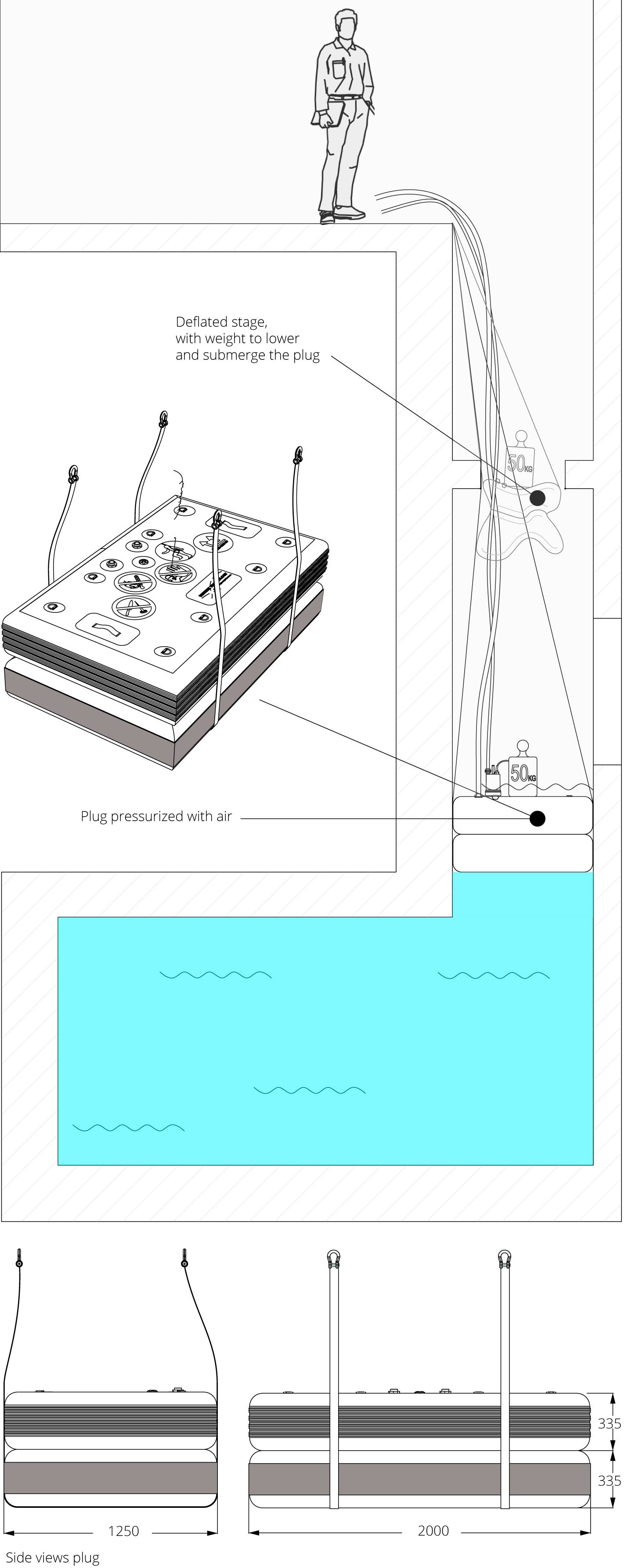

Due to the very restricted space in and around the shaft and because the valve has to be removed through the hydro-turbine after use, the only solution is to deploy a specially designed inflatable valve that has been custom-made for the project.

Specifications and operational requirements

The inflatable valve must meet a number of specific requirements:

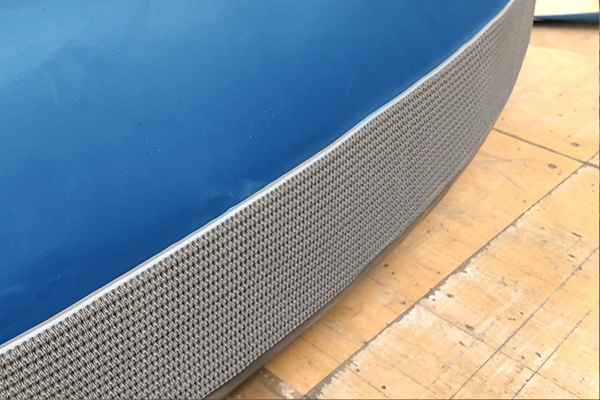

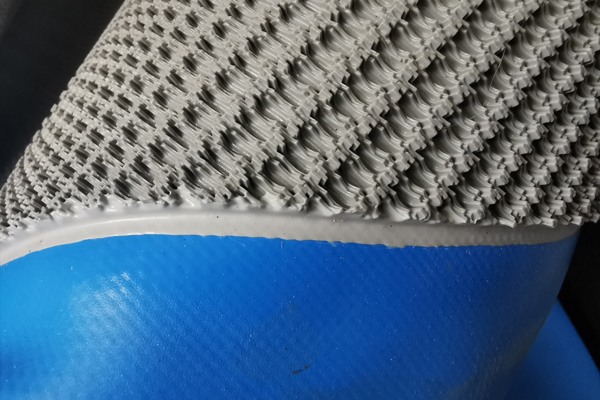

- The shaft wall is abrasive. The valve must therefore be wear-resistant and be highly puncture resistant. We tested various materials for puncture resistance and selected the most suitable one. You can watch the video of the test below.

- It must be possible to work on top of the valve. The top of the valve must therefore feature a flat surface (i.e. not convex or cylinder-shaped).

- The water contains a high concentration of iron(III) chloride (FeCl3). The valve must therefore be able to tolerate this.

- The rising water level exerts great pressure forces on the valve. The clamping force of the inflatable valve against the shaft wall must be sufficient to absorb these forces.

- When deflated, the valve must be as compact as possible.

- The valve must be able to withstand temperatures of between -20 and +70 degrees Celsius.

- The valve must be protected against excessive pressure.

- It must be possible to fill the valve with both water and air.

Design and result

We came up with the following design based on the client’s wishes and requirements.

The inflatable unit consists of two linked chambers that can be partly or fully filled with water.

When deflated, yet partly filled with water, the valve is lowered into the shaft and placed in the required position. The inflatable plug can then be completely filled with water. The valve can then be inflated to the correct pressure until the required clamping force had been reached.

After use, the water can be pumped out of the valve and the air sucked out, leaving a small, flexible package that can be pulled out of the shaft.

Anti-slip

One of the inflatable chambers features an anti-slip coating all around to create a very high friction coefficient against the adjacent shaft wall.

Sealing rubbers

The other chamber is fitted with special rubber seals all around to prevent as much water as possible from leaking through.

Questions?

Do you have questions or want more information? Please feel free to contact us. Call us at +31 (0)316-250830. But even easier: fill out the contact form below directly. We will contact you as soon as possible!

Contact form

Contact form +31 (0)316-250830

+31 (0)316-250830