- Architecture

- Industry

- Leisure

- Technology Center

- uk >

- Industry >

- Miscellaneous industry >

- Insulating covers

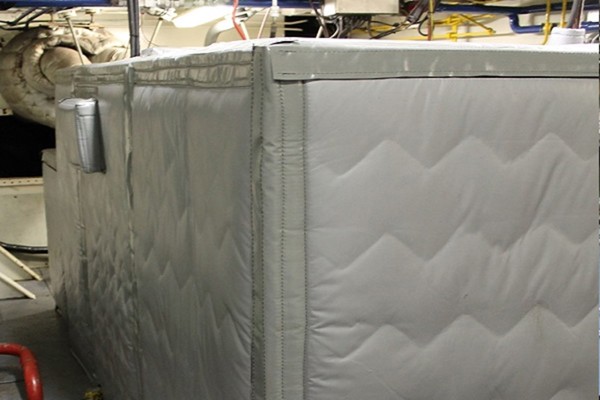

Insulating covers

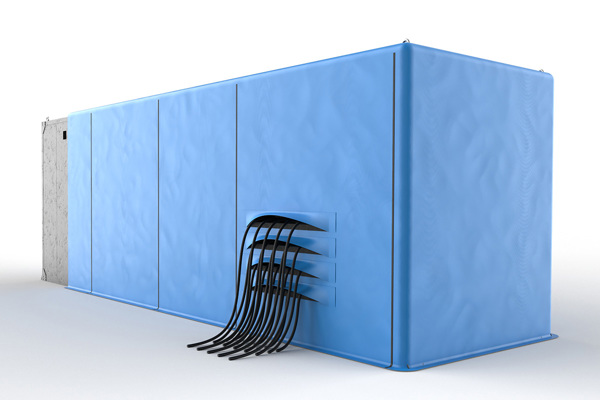

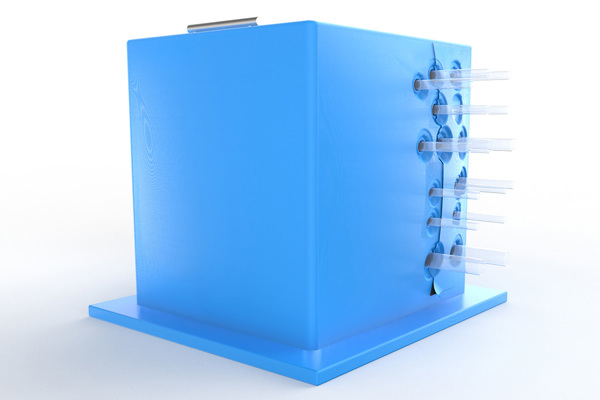

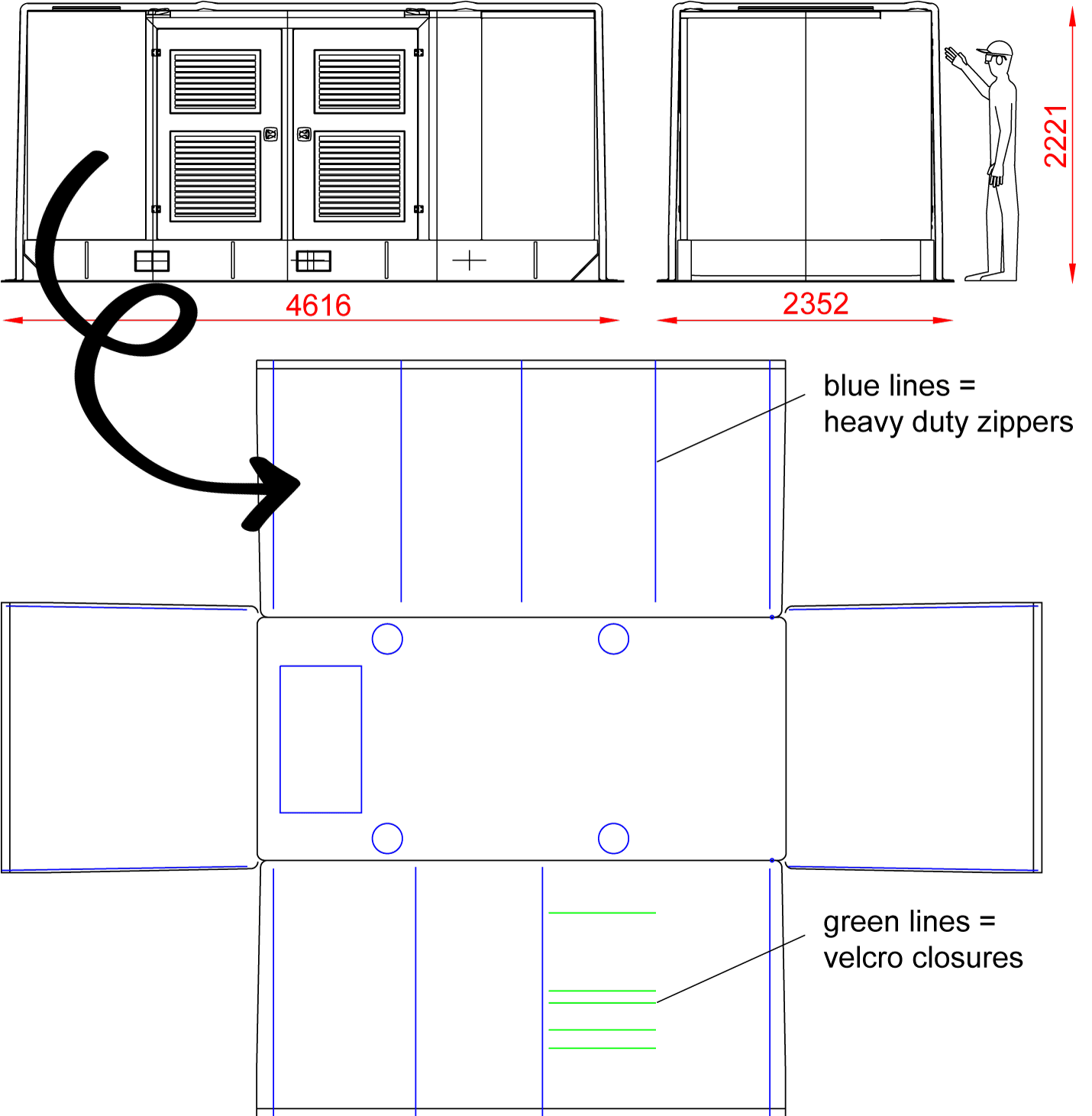

A flexible insulation cover can be made up of several components or modules so that it remains manageable. In addition, openings (such as for pipes or connections) can be provided. Even for very complex shapes, we can produce customised covers that fit perfectly.

The thermal insulation covers can be connected or joined with Velcro, as well as with special heavy-duty zips, which can still be opened and closed under even in the harshest of conditions (cold, damp, salt water, dirt).

Insulating covers can be used, for example, for on-site thermal insulation (and therefore keeping warm) of manifolds (with hose outlets), hydraulic hoses (preventing hydraulic oil from becoming too cold) and (emergency) generators.

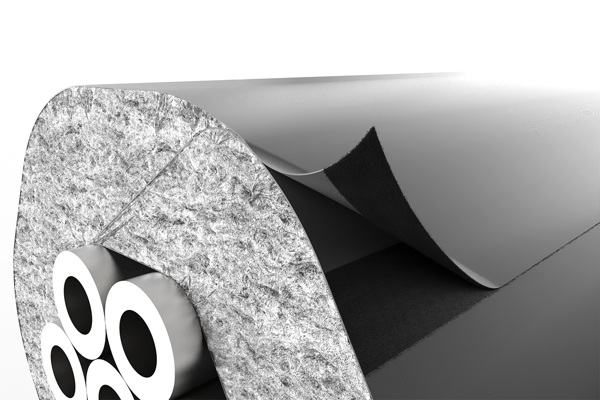

Multi-layer construction

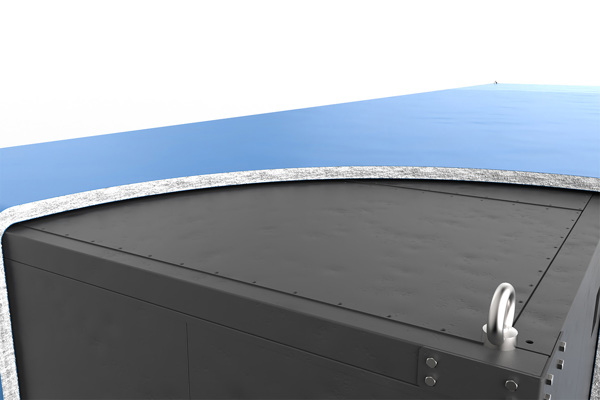

Insulating covers – intended for thermal insulation or soundproofing – are often made up of several layers (sailcloth and insulation material).

With a multi-layer construction, a u-value of 0.62 W/m2 K or even lower can be achieved.

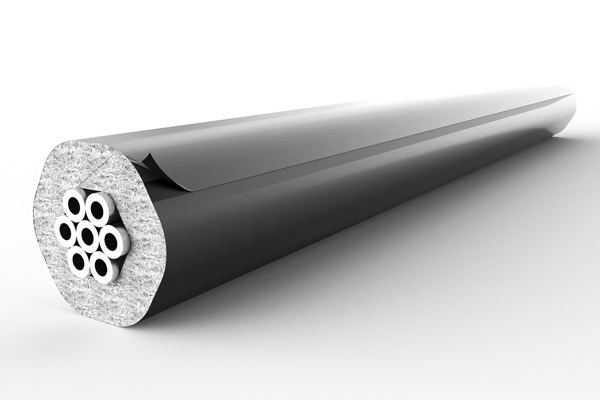

Thermally insulating polyester wool

As insulation material, we generally use polyester wool, which is flame-retardant and has a fire class of B, s2-d0 (in accordance with EN 13501-1) and B1 (in accordance with DIN 4102).

The thermal insulation value of polyester wool in accordance with DIN52612 is on average: lambda = 0.040 W/m K. See also:

Capable of withstanding high temperatures

Insulating covers can also be made that are non-flammable or that can withstand very high temperatures. Due to the aluminium coating of this material, it also has an extremely low emissivity (<0.10) and reflects heat, thus providing additional insulation.

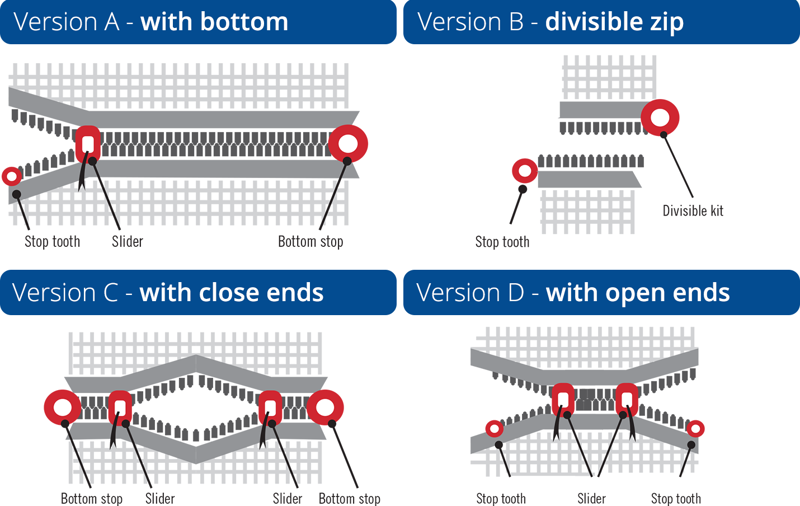

Heavy-duty zips

The insulation covers can be made separable and can include manholes or passages for pipes. This can be achieved using Velcro, but when it comes to large sections that must be frequently disconnected and reconnected, or when high loads are applied to the connection, heavy-duty zips are used.

These heavy-duty zips are suitable for use in the harshest of environmental conditions: frost, snow, water, salt water, dirty seawater and so on.

The teeth of the heavy-duty zips are made of plastic (POM) and have high mechanical strength and shock resistance.

Advantages and features

With a tailor-made flexible insulation cover from Buitink Technology, you can improve your efficiency and work faster and more efficiently:

- Equipment onsite can be protected from extreme cold, and as a result freezing, for example, of hydraulic oil or other oil, is prevented;

- The covers are flexible and can be folded and stored and transported in a small and compact package;

- Relatively speaking, the covers are very lightweight (for example, as compared to an alternative in the form of sandwich cladding);

- The thermally insulating covers also protect the equipment from rain, snow, wind and dirt;

- With Velcro and heavy-duty zips, the covers can be made modular and connectable;

- The covers can be fully customised, including openings, manholes and so on;

- Depending on the location and insulation requirements, we can make the cover in any required u-value (thermal insulation value).

More information

Buitink Technology is a resourceful company with original ideas and ingenious products. Call Buitink Technology: +31 316 25 08 30, email: [email protected] or leave your contact information:

Call me

Call me More information

More information +31 (0)316-250830

+31 (0)316-250830