- Architecture

- Industry

- Leisure

- Technology Center

- uk >

- Industry >

- Inflatable floats >

- Convertible Salvage Bags

Convertible Salvage Bags

At the request of its customers and users, Buitink Technology developed the so-called Convertible Salvage Bags (CSB's for short).

To create buoyancy and keep objects afloat (e.g. pipelines, shipwrecks, etc.), we produce airtight closed flotation cushions called EFB's (Enclosed Flotation Bags):

For lifting and hoisting (sunken) objects under water, we have developed the so-called Parachute Bags, which are open at the bottom so that the air can escape and the internal overpressure in the Parachute Bag does not become too high during ascent:

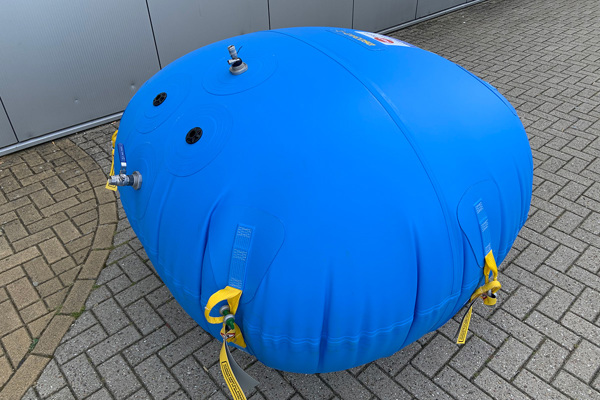

As both systems and methods are often used during the same (salvage) operation, we have developed one solution that combines both buoyancy and ascending lift capacity: the Convertible Salvage Bag, or CSB for short. A CSB is basically an EFN that can be transformed into a parachute bag on site, and vice versa, in an instant.

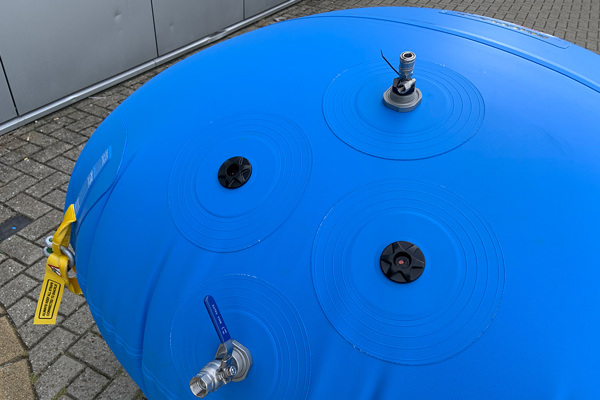

The CSB is fitted with one or more large round closable openings (with a diameter of about 146 mm) at the bottom, which can be set up during lift operations and closed again when objects need to be kept afloat or gain more buoyancy.

With one type of buoyancy cushion, it is therefore possible to carry out two different gassing operations! This saves on investment costs, but also on storage, transport and handling costs. In addition, the user is much more flexible during a salvage operation on or under the water, and only on location does it become apparent that both a lift cushion (to raise the sunken object) and a buoyancy cushion (to then float the object) are needed.

Advantages and specific features

Advantages and specific features of the Convertible Salvage Bag (CSB):

- Two-in-one solution: The CSB combines the features of both EFBs (Enclosed Flotation Bags) and Parachute Bags in one product.

- Flexibility of use: The CSB allows the user to choose between creating buoyancy (like the EFB) or raising sunken objects (like the Parachute Bags) depending on the salvage operation required.

- On-site adaptability: The CSB can be easily and quickly transformed between its two functionalities, meaning the user can respond to unexpected needs during a salvage operation.

- Large lockable openings: The CSB has one or more large round lockable openings (approximately 146 mm in diameter) at the bottom, which can be opened or closed depending on the disposal requirement. The plastic closure covers remain connected to the CSB via a cable so that they cannot float away or get lost.

- Cost savings: By using the CSB, companies can save on investment costs, storage, transport and handling because they no longer need to purchase and maintain both types of flotation cushions (EFB and Parachute Bags).

- Increased efficiency: Users no longer need to carry different types of flotation cushions to a salvage operation, saving both time and effort.

- Increases operational flexibility: The versatility of the CSB allows users to adapt to unforeseen needs that may arise during a salvage operation, without the need for additional equipment.

Standards

All of Buitink Technology's underwater cushions are developed according to IMCA D-016 standards.

Features CSB

- The polyester fabric and EVA/PVC co-polymer coating make the material very flexible and very easy to repair (with glue or a hot air blow dryer).

- Float cushions from Buitink Technology do not have sharp corners (they are rounded and smooth), making these underwater cushions sturdier and less likely to be damaged.

- Float cushions require little maintenance and are very easy to clean.

- The flotation cushions can be used in temperatures down to -22 degrees Fahrenheit (-30 degrees Celsius).

- Special (TPU) coatings and aramid/ Kevlar fabrics can be added to increase strength up to 75% and cold resistance up to -40 degrees.

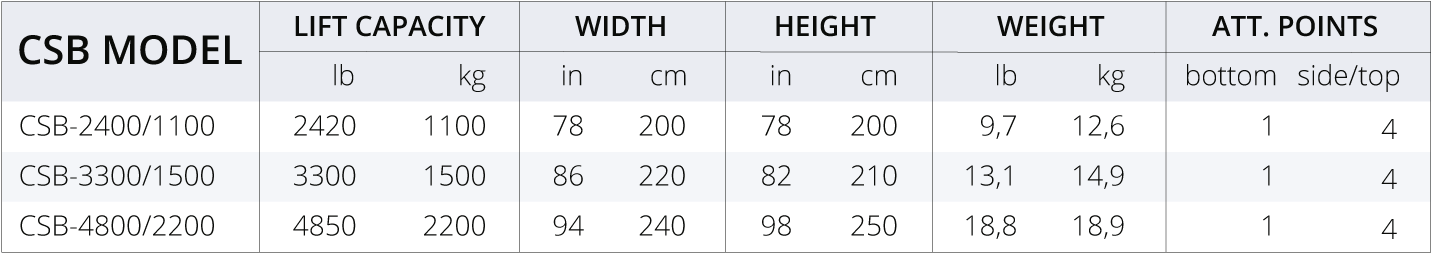

Models and specific features

High-quality materials and production

- NO glue is used during the manufacturing process. All patches and seams are HF welded (High Frequency welded).

EVA/PVC copolymer-coated polyester fabric - very strong and heavy-duty. - Tensile strength of the fabric: 8,000 N/5 cm (1798 Lbs/5 cm).

- Resistance to puncture / puncture: 2,150 Newtons / 483 Pounds-Force (unlike competing products, which often do not exceed 1,750 Newtons / 393 Pounds-Force).

- Resistant to many chemicals.

- High UV resistance.

- Very easy to repair (with glue or a hot air dryer), unlike PU- or TPU-coated materials.

- Highly flexible and lightweight material.

- Equipped with pressure relief valves.

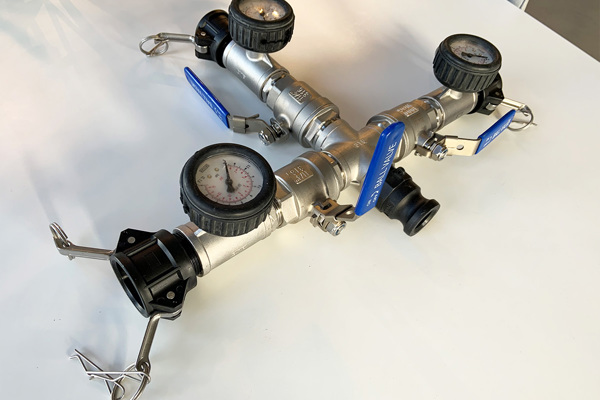

Optional: manifold large

Optional: manifold small

Optional: connector pressure measurement from cushion

More information

Buitink Technology is a resourceful company with original ideas and ingenious products. Call Buitink Technology: +31 316 25 08 30, email: [email protected] or leave your contact information:

Call me

Call me More information

More information +31 (0)316-250830

+31 (0)316-250830