- Architecture

- Industry

- Leisure

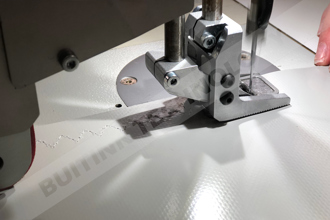

Bellows | expansion joints

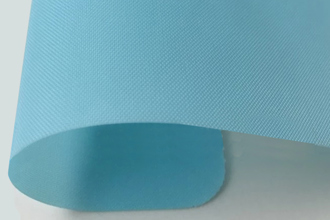

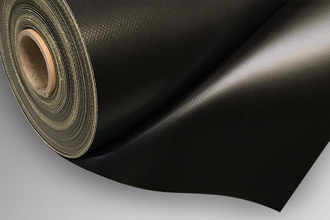

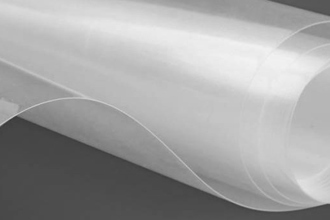

We supply flexible connections made of all kinds of flexible synthetic materials of constructions like: PVC, poly urethane (PU and TPU), silicone coated fabric, ETFE foil, PTFE coated canvas as well as PFA, FEP, THC en PTFE cross film.

You want a flexible joint, but no standard solution is available? You can count on us for design and engineering up to construction and installation on site as well as operational support.

Advantages Buitink Technology's fabric expansion joints

The advantages of ordering fabric expansion joints at Buitink Technology:

- Custom product;

- In house design, engineering, 3D drawing and work scheduling;

- Completely in house produced;

- Extensive modern machinery and tools for in house processing of flexible plastics;

- Large production capacity through our 5 designers/schedulers and 20 production employees;

- On request our own technicians will do the installation on site;

- We are VCA certified;

- Fast delivery;

- All dimensions possible;

- Various materials of construction are on stock;

- Optimum compensation of vibration and motion;

- Optional sound insulated sleeves and expansion joints are possible as well.

Do you have a question or would you like to receive a price indication?

Simply fill out our contact form:

Air- and flue gas pipes

Often fabric based expansion joints are applied to make connections in air- and flue gas pipes. These joints compensate size differences in the pipelines to be connected. Besides they absorb any movement and vibration in a pipeline network e.g. as a result of thermal expansion and/or vibration of pipes and tubes.

Water- and air tight is feasible

Fabric expansion joints can be used to make a watertight connection of a building- or wall pass through as well. E.g. when a pipe duct is moving or vibrating in a roof pass through.

Suitable for hot air and liquids

Fabric expansion joints of Buitink Technology are suitable for warm or hot air, dry and wet (condensing) air as well as liquids. We make expansion joints for all kinds of fluids.

Food industry

Besides we make also expansion joints out of materials applied in the food industry. Usually we apply PTFE sheet, PTFE coated fiberglass cloth or ETFE foil in the food industry. These materials are suitable in food production facilities

Quality and quality assurance

Quality and quality assurance are extremely important for Buitink Technology. Our aim is to deliver the right product without failures within the agreed delivery time.

Every sleeve we produce gets a unique track and trace number. Through this number we know exactly type, color, brand and batch number of materials used for this specific product as well as who, when and how long employees worked on this product.

We are equipped to perform in house extensive tests on materials and seals as well as bending and fatigue tests.

More info and examples are found on our website:

In the rare event (despite of our quality control) of material or quality problems we can quickly trace and analyze the problem together with our customer and give feedback on potential material defects to our supplier. Preventing any future problems!

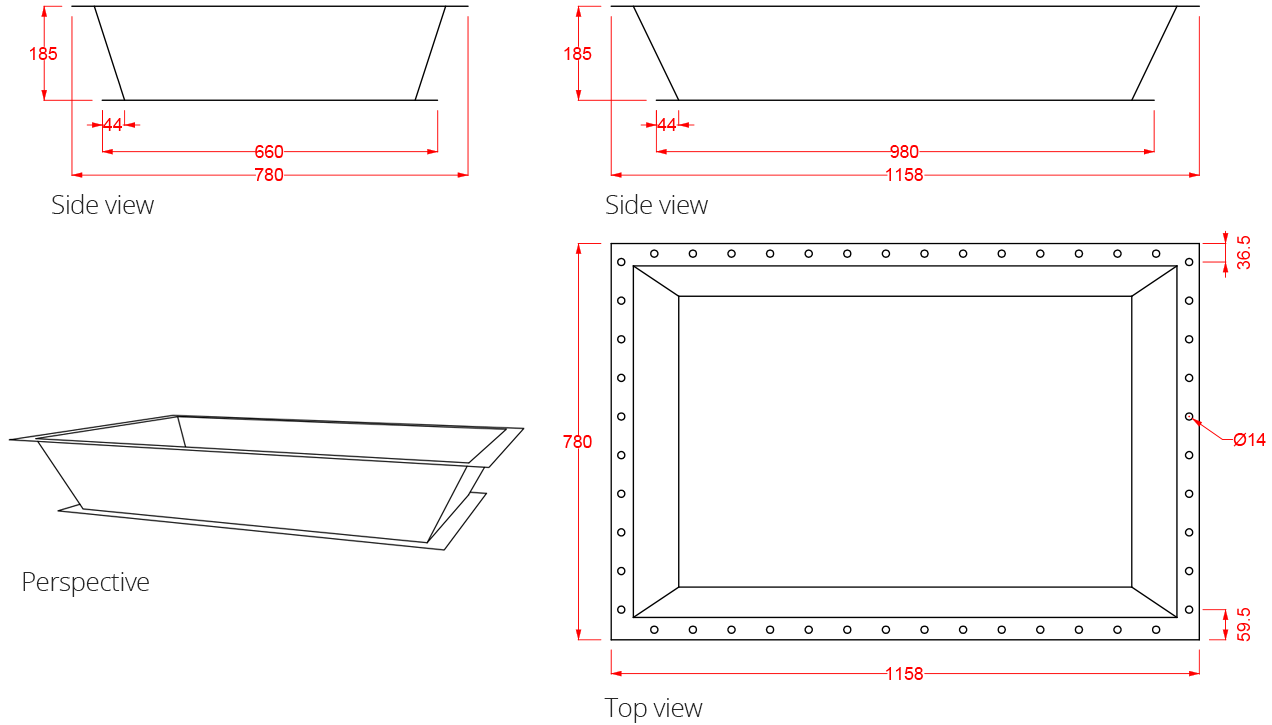

Before starting production of a new type of fabric expansion joint we always sent a design drawing to our customer for approval.

Automated stock management system

We have a large stock of materials to produce fabric expansion joints. This stock is accurately monitored automatically; a minimum stock of each material of construction is guaranteed to always deliver orders in time. The automated stock management system gives an alert when the stock of a specific basic material is below minimum level.

Custom service

We design a fabric expansion joint based on the requirements dictated by the customers application.

Following aspects are taken into consideration:

- Composition of the fluids in contact with the expansion joint;

- Temperature of the fluid;

- Pressure or vacuum in the system;

- Environmental temperature;

- Type of mechanical motion to be compensated (movement, vibration, motion, applied forces);

- The scale of movement, vibration and/or motion;

- Climate conditions (inside/outside, humidity, weather conditions, UV-radiation, etc);

- Mechanical loads on the fabric expansion joints;

- Requirements based on air- and liquid densities;

- Installation requirements and - space as well as accessibility;

- Is fast installation required?

Above aspects are the basis for a fully custom made product, that corresponds to your demands and delivered fast as well!

We solve it with a lightweight flexible solution!

since 1948

Questions?

Do you have questions or want more information? Please feel free to contact us. Call us at +31 (0)316-250830. But even easier: fill out the contact form below directly. We will contact you as soon as possible!

Contact form

Contact form +31 (0)316-250830

+31 (0)316-250830