- Architecture

- Industry

- Leisure

- uk >

- Architecture >

- Lightweight canopies >

- Dry run on Jersey Island

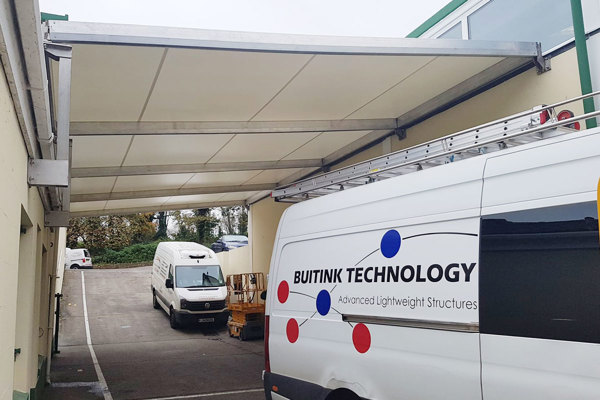

Dry run on Jersey Island

Buitink Technology has designed, manufactured and assembled on Jersey a prefabricated lightweight tensile structure with the function of dry running.

Modular, dismountable and deployable worldwide

The entire canopy - including all wall mounting plates and brackets - was designed and made based on photos and digital measurements. Next, the dry run was transported to the site as a prefabricated construction kit, where it was assembled by our technicians within a few days.

The dry running of Buitink Technology consists of a modular profile system. This system is suitable for building permanent structures and shelters, but is also very easy to dismantle, move and rebuild (elsewhere).

The profile system can be used to create prefabricated lightweight custom solutions that can be assembled on site very quickly. Moreover, the system can be packaged and transported very compactly.

This makes the dry run of Buitink Technology a solution that is delivered and deployed worldwide.

Initial situation

On the basis of a program of requirements, photographs and (global) measurements of the situation, Buitink Technology has made a design of the dry run.

Image: Initial situation

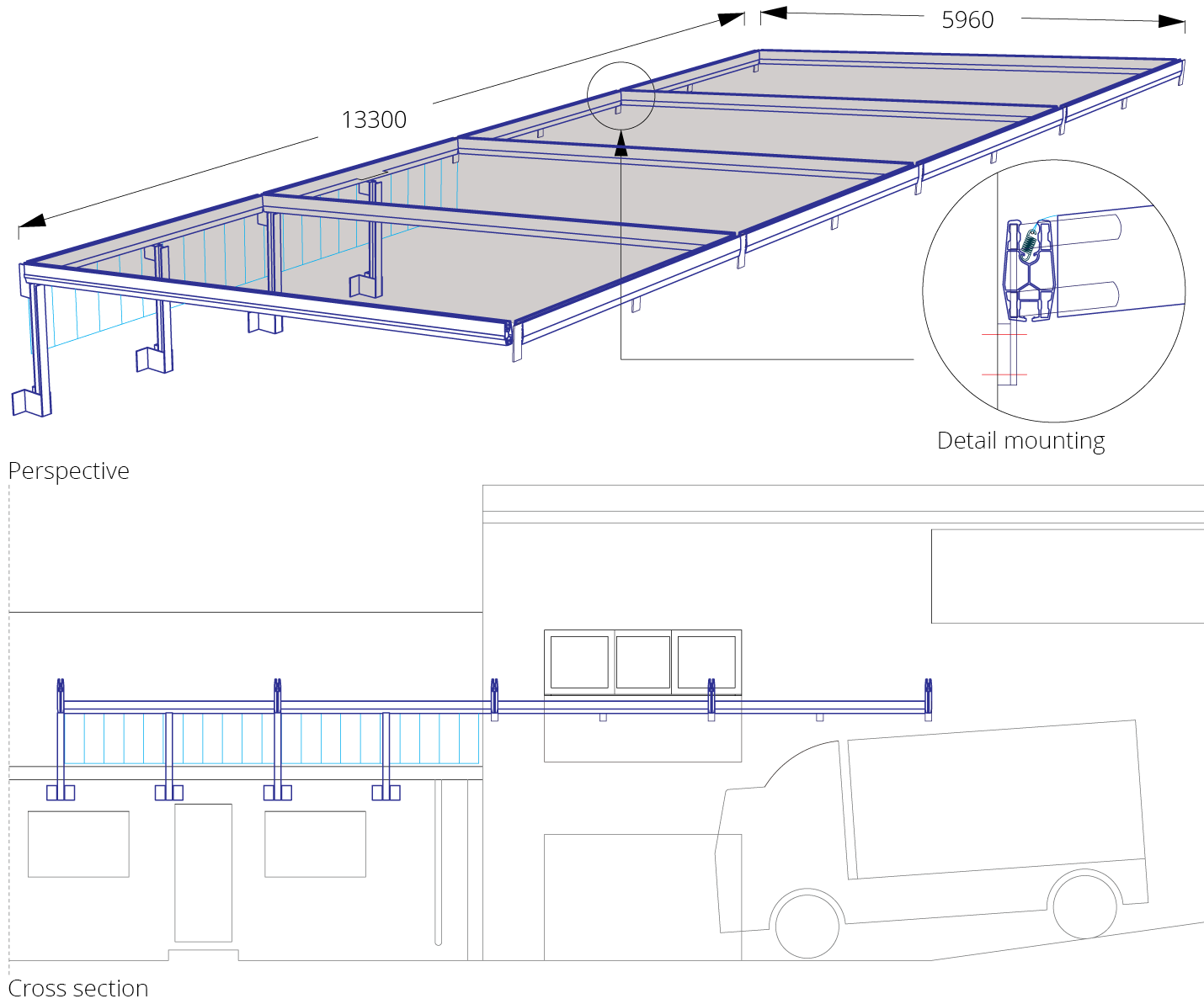

Design and requirements

The following requirements and aspects were taken into account in the design:

- A dry walkway must be built between two buildings to protect them from the weather during loading and unloading;

- The canopy must be translucent;

- Proper drainage must be ensured, to one side;

- Direct rainfall from the sides should be avoided as much as possible;

- The canopy must be able to withstand all weather conditions (wind, snow);

- The wall fixings must also be included, so that the dry run can be delivered to the site as a ready-made kit.

On the basis of the above requirements and the desired dimensions, we have designed the lightweight dry roof below.

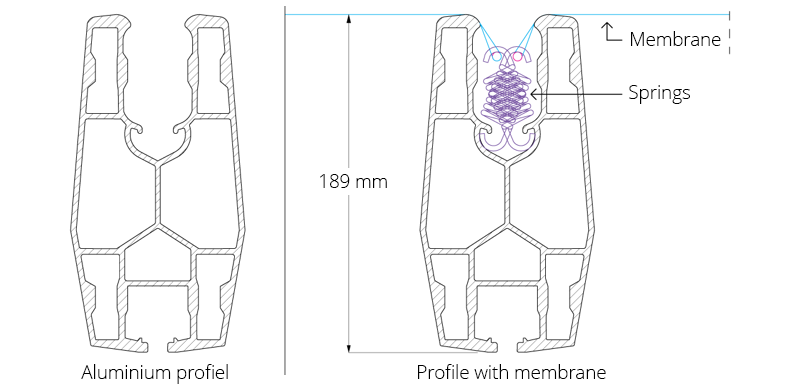

Framework materials

The dry run is made of top-quality materials of European manufacture.

- The main supporting structure is made of a special aluminum extrusion profile, which can be coated or anodized in any color;

- The tensioned cloths/membranes are mounted in this profile by means of stainless steel springs;

- The profiles are interconnected and attached to the surrounding walls using stainless steel sketch plates, stainless steel fittings and stainless steel auxiliary constructions.

Membrane material

The membranes themselves are made of a white, translucent membrane fabric, type TX30-III by Serge Ferrari. This membrane quality is translucent, flame retardant, dirt repellent and has an expected life span of over 25 years. The specifications of this material:

Membrane possibilities

A dry run from Buitink Technology can be equipped with all possible types of fabric and foil: closed tarpaulin, in all possible colours, translucent or non-translucent, fully transparent (with even transmission of UV rays!), sunproof gauze fabric, rain breaking gauze fabric, (full colour) printed, etc.

The following links give examples of the many material options we offer:

- Tight tarpaulin

- Gauze cloth (wind breaking, sun protection and blocking direct rain)

- ETFE folly transparency

- Full colour printing

A dry run canopy can also be partly or fully provided with a (full colour) print, so that your canopy is fully adapted to the surroundings and what you like!

For more information on the top-quality full-colour printing technique that can be used, please see:

Project data dry running

| Dimensions: | 13,3 x 6 metres (approx. 80 m2) |

| Material: | Serge Ferrari Flexlight-XtremTX30-III | Specs > |

| Client: | Valley Foods, Jersey |

| Main contractor: | Rowney Sharman, Jersey |

| Dry running: | Buitink Technology |

| Implementation year: | 2021 |

Transport and packaging

The prefabricated dry roofing measuring approximately 13.3 x 6 metres (approx. 80 m2) weighs 750 kg. That is only 9.4 kg per m2 of weight.

This 13.3 x 6 metre canopy can also be shipped very compactly. Only a space of approximately 570 x 120 x 30 cm is required.

Assembly and anchoring

As well as the dry well itself, we can also make and deliver all the wall fixings and anchors. The dry well then arrives at your door as a complete kit, ready for assembly!

The assembly of the dry run is easy. We supply an assembly manual, which you can follow step by step. Within Europe, we can provide supervision or the entire assembly, outside Europe we can provide supervision/ guidance if required.

Below are images and videos that give a good impression of the wall anchors and brackets and the assembly of the dry run.

Advantages of our dry running

A dry run of Buitink Technology has a number of advantages:

- Easy to build;

- The dry run is designed as a kit, lightweight and very compact to ship all over the world;

- It can be equipped with wind- and rain-breaking and sun-blocking gauze cloths, but also with dense tarpaulins or even transparent cloths as an alternative to a glass roof;

- Can be fitted with solar panels;

FAQ lightweight dry running

Is a lightweight dry run suitable for permanent use?

By carefully calculating in advance during the engineering process the load that rain, wind and snow can exert on the dry lining and façade construction, this is an ideal lightweight solution that can be left in place permanently.

Does a lightweight dry run only offer protection from rain?

Depending on your wishes, the roofing can serve as a waterproof roof, but also as a sunshade and windbreak if you use side walls. There is a wide choice of different materials that block or let through wind, water and light.

Can you also easily dismantle the lightweight dry run afterwards?

Because we use a specially developed modular POV® profile, assembly on site and disassembly afterwards is relatively easy. You can therefore dismantle the dry run and put it back at another location, for example. You can also change the cloths to create a completely new set-up.

How do I find out if a lightweight dry run is a good option in our case?

After assessing the situation in combination with your wishes, we can start a design and engineering process that will provide a clear picture of the technical feasibility on site and whether the cost fits the budget.

Does it take a long time to assemble the lightweight dry run?

Everything is prefabricated in our own factory and packed compactly so that, once on site, the profile system can be quickly assembled, the curtains retracted and dismantled. Of course, the lead time is entirely dependent on the size of the project and whether the preparations at the building site have been carried out as agreed.

Can the banners also be fitted with advertising?

The canvases of the Lightweight Dry Run can be provided with full colour printing. This may be to personalise the look of the end result, but also to show advertisements. In combination with a special treatment, a 10-year guarantee can be given on the colourfastness of the full colour print.

In which countries do you install this lightweight dry run?

Because the entire system is prefabricated in our own factory in Duiven and is packaged very compactly, we can send it all over the world at relatively low cost. In the Netherlands and Belgium we assemble with our own team. In all other places in the world, we can supervise the assembly.

What maintenance should be carried out on the lightweight dry run?

Contamination of the cloths strongly depends on the location where the dry run is placed. A wooded area with a lot of leaves may require a higher maintenance frequency than a coastal area, for example. Depending on the choice of cloth, most dirt will generally be removed by the rain. Upon delivery, you will receive maintenance advice that you can easily carry out yourself.

Can you change the cloths of the lightweight dry roof afterwards?

If you want to replace a shade cloth afterwards, for example with a transparent and light-transmissive ETFE foil or vice versa, you can. Thanks to the clever POV® profile system, all types of cloth can easily be retracted or extended afterwards.

Is a lightweight dry run always mounted on the façade or between 2 façades?

That is indeed one of the possibilities, but in addition, a freestanding construction or a partially freestanding construction can also be built. The foundation is also a component for which we can provide advice.

Location

Valley Foods Ltd | La Solitude Farm | JE3 6DF | St Martin Jersey

Questions?

Do you have questions or want more information? Please feel free to contact us. Call us at +31 (0)316-250830. But even easier: fill out the contact form below directly. We will contact you as soon as possible!

Contact form

Contact form +31 (0)316-250830

+31 (0)316-250830