Inflatable Work Platforms for Complex Industrial Access

Inflatable work platforms create a stable, temporary work floor in places where traditional scaffolding is impractical or impossible.

Work floors for silos, tanks and confined spaces

When maintenance, inspection or repair work needs to be carried out inside tanks, silos or other confined spaces, traditional scaffolding often cannot reach the required height or shape. An inflatable work platform provides a fast, safe and cost-effective temporary floor solution that can be installed through small access openings and creates a stable working surface.

Typical access challenges in confined industrial environments

These challenges require a different approach to internal access.

- Safe maintenance is required inside confined or enclosed spaces.

- Access is limited to small manholes or narrow entry points.

- Building internal scaffolding is impractical or too time-consuming.

- Equipment geometry is irregular, tapered or non-standard.

- A stable temporary work floor is needed at a specific height.

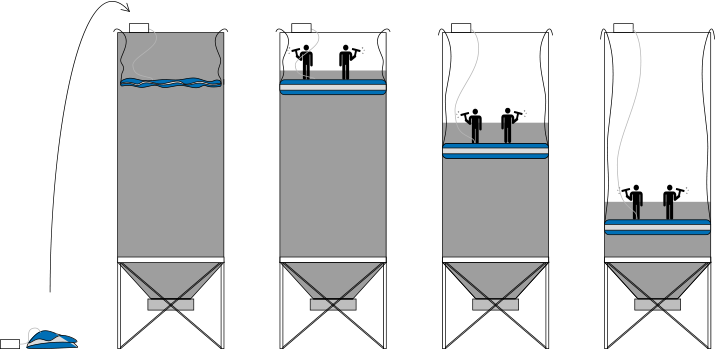

How it works

An inflatable work platform is lowered into the confined space via a manhole or access opening. It is then inflated using compressed air or an electric blower. When correctly pressurised, the platform presses against the walls and creates a stable floor at the desired work level.

Product variants

Work Platform S

Compact, versatile and quick to install — ideal for smaller silos and tanks.

Work Platform XXXL

Engineered for large vessels up to approx. 30 m diameter and customised requirements.

Technical Specifications

Engineered for industrial safety, performance and reliability in demanding environments.

- CE-certified and compliant with international safety standards.

- Load capacity between 200–500 kg, depending on platform size and design.

- Temperature resistance up to 300 °C (special high-temperature versions available).

- Water- and chemical-resistant materials available for industrial environments.

- Bespoke engineered access solutions tailored to each project.

Typical Applications

Silo Cleaning & Repair

Inflatable platforms make inspection, cleaning and repair of silo interiors safe and efficient.

Platform for silo cleaning & repair

Platform for Mixers

Designed for mixer maintenance and internal access where conventional flooring is impossible.

Key benefits

- Rapid installation and removal without internal scaffolding.

- Minimal internal logistics, as the platform passes through small access openings.

- Adaptable to different diameters, heights and internal geometries.

- Reduced downtime compared to traditional internal scaffolding systems.

Safety & Standards

Inflatable platforms are designed and tested for safe use in industrial confined spaces. Training, risk assessment and proper PPE remain essential for all maintenance operations.

User Manual

For safe and correct use of the Inflatable Work Platform with heat-resistant cover, please refer to the official manual.

FAQs

How fast can an inflatable work platform be installed?

Installation typically takes between 5 and 15 minutes, depending on platform size and access conditions. The platform is brought in deflated, positioned at the required height and inflated using compressed air or an electric pump.

Is an inflatable work platform safe for confined spaces?

Yes. Inflatable work platforms are specifically designed for safe use inside confined spaces such as silos, tanks and vessels. They create a stable, non-slip working surface without the need for internal scaffolding or permanent fixings.

What load capacity does an inflatable work platform have?

Typical load capacity ranges from 200 to 500 kg depending on size and design. Each platform is engineered and tested for a defined working load in accordance with CE requirements.

Can the platform damage tank, silo or vessel walls?

No. Contact surfaces are soft and flexible and are designed to distribute pressure evenly. This prevents scratches, point loads or damage to coatings, stainless steel or composite materials.

What is the minimum manhole or access opening size?

Platforms can typically be brought in through openings of Ø 50–60 cm. The exact minimum size depends on platform type and configuration.

Can one inflatable platform be used at different working heights?

Yes. The platform can be positioned and inflated at different heights during the same maintenance shutdown, allowing access at multiple levels.

Is the platform suitable for ATEX or hazardous environments?

The basic structure is passive mechanical and can be manufactured from anti-static and chemically resistant materials. Suitability for ATEX zones must be confirmed as part of a site-specific risk assessment.

How is the platform inflated and kept safe?

Inflation is done using compressed air or an electric blower. Integrated pressure relief valves prevent overpressure and ensure stable operation during use.

Is scaffolding still required when using an inflatable platform?

In most cases no — the inflatable platform replaces internal scaffolding by creating a temporary work floor directly at the required height.

Can the platform be customised to specific dimensions?

Yes. Platforms are custom-designed to match the diameter, shape and internal geometry of the application, including tapered or irregular spaces.

How compact is the platform during transport?

When deflated, the platform is rolled into a compact package that can typically be carried by one or two people and transported in a van or crate.

Can inflatable work platforms be reused?

Yes. Platforms are designed for repeated use across multiple maintenance cycles and projects, provided they are used within their design limits.

How does an inflatable platform compare to traditional scaffolding?

Compared to scaffolding, inflatable platforms offer much faster deployment, less downtime, lower internal logistics and no need for permanent fixings.

In which industries are inflatable work platforms typically used?

Typical industries include chemical processing, food production, energy, refining, water treatment, offshore and heavy industry.

Is training required to use the platform?

Basic instruction is usually sufficient. Clear setup procedures and safety guidelines are provided with each platform.

Contact

Need tailored advice or a quote? Our technical team is ready to support you. Please feel free to contact us. Call us at +31 (0)316-250830. But even easier: fill out the contact form below directly. We will contact you as soon as possible!

Questions?

Do you have questions or want more information? Please feel free to contact us. Call us at +31 (0)316-250830. But even easier: fill out the contact form below directly. We will contact you as soon as possible!

Contact form

Contact form +31 (0)316-250830

+31 (0)316-250830